What Sets VEEMSurf Propellers Apart?

The VEEM Surf propeller is the latest in surface-piercing propeller design. It is loaded with design innovations including the VEEM Interceptor™ technology that makes it unbeatable when seriously high thrust must be applied in a smooth, quiet and reliable manner. Using ‘shock-free’ blade sections and optimized blade areas, you can rely on smooth operation in any condition. VEEMSurf propellers are a premium surface piercing solution optimized for high-speed vessels that demand smooth operation, high thrust, and flexibility through in-situ pitch tuning. They leverage VEEM’s advanced engineering, CNC precision, and patented technologies to deliver performance that stands out in demanding marine applications.

Custom Design & Engineering

- VEEM propellers are not off-the-shelf standard parts. Each propeller is engineered to match the vessel’s hull form, power, and mission profile using advanced CFD and hydrodynamic analysis.

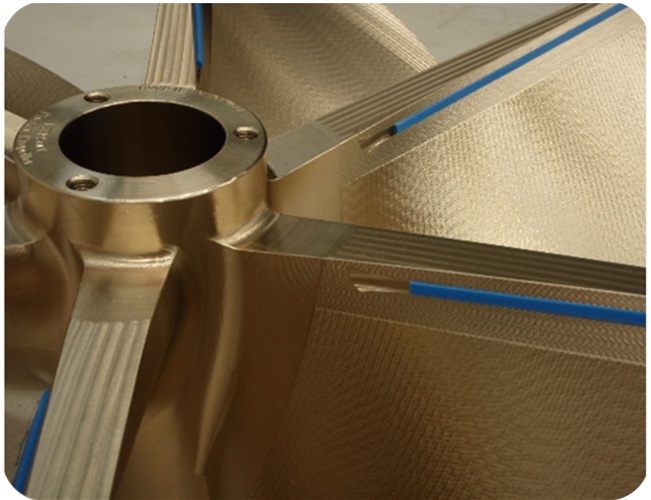

Precision Manufacturing

- Every VEEM propeller is fully CNC-machined — not just finished surfaces, ensuring extremely accurate blade geometry, better balance, and higher repeatability than traditional Class 1 profiles.

Interceptor™ Pitch Adjustment

- Originally a VEEM innovation (and now part of several VEEM lines), Interceptor™ allows adjustment of the effective pitch in the water (no haul-out required), providing tuning flexibility and performance gains.

Key Features

- Surface Piercing Configuration – Designed to operate partially above the waterline at high speed, reducing drag and maximizing thrust efficiency.

- VEEM Interceptor™ Technology – Standard on VEEMSurf series; enables in-situ effective pitch adjustment to fine-tune performance without lifting the vessel.

- Cleaver-Style Blade Geometry – High-speed optimized blades for thrust and reduced ventilation.

- Custom Engineered per Boat – Rake, skew, thickness, camber, and other geometries tailored to each vessel’s hull, engine, and operating profile.

- Shock-Free’ Blade Sections – Designed to maintain smooth hydrodynamic flow, reducing pressure spikes that cause noise, vibration, and cavitation.

- High Precision Manufacturing – CNC-machined profiles with quality balancing and surfacing standards (ISO 484/2 Class S and ISO 1940/1 G2.5).

There are no products to list in this category.